Chargers for camera batteries

By chargers, we basically mean a device for charging batteries. The charge controller contained in the device controls the charging process. In most cases, the charger is supplied with power from the public power grid using a mains adapter. However, mobile chargers are also available and are mainly used for smartphones or in model making. Many devices have the charge controller built directly into the battery-powered end user. Then there is no need for the charger and you only need the power supply unit and a suitable voltage source.

What chargers don't like at all

Chargers are sensitive when it comes to overcharging, deep discharging and overheating. They significantly reduce their service life and capacity, and may even cease to function altogether. In addition, chargers react to the events described above by not fully charging the battery. Depending on the type of rechargeable battery, the manufacturer's instructions regarding the application and use of the charger must be explicitly taken into account so that it lasts as long as possible and fully utilises the capacity of the rechargeable battery to be charged.

Does a low price mean poorer quality?

In this case, the circumstance described above actually applies. Because of a short battery life and the constant acquisition costs for replacements, cheap chargers are not profitable. Smart chargers in all price ranges are available on the market and there are a variety of good manufacturers and high-quality brands.

A product overview

We all know plug-in chargers. The charging circuit is hidden in the plug of the device, as the name suggests. Normally, the chargers are for charging standard round cell batteries. They work very efficiently and have a low risk of self-discharge. The charging slots are also integrated directly into the device and usually the devices offer space for two or four batteries. Larger devices are rarely found in the private sector. Fast chargers work much faster than conventional chargers. However, there is no precise definition here. They charge a battery in less than two hours.

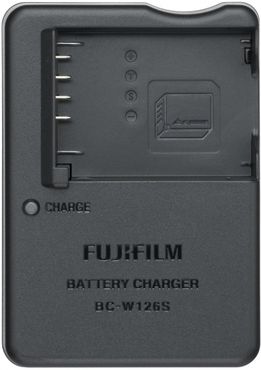

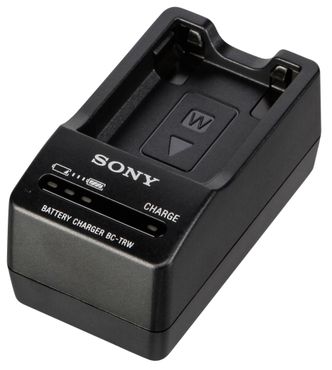

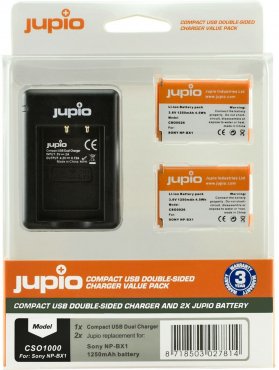

Simple chargers consist of a separate plug-in power supply and a charging circuit in the device. They are usually used to charge lithium-ion batteries, such as those found in most cameras. Charging is done with a constant voltage. The devices cannot be controlled or monitored. They also do not indicate the end of the charging process. Some suppliers have a timed cut-off device built in. If the cut-off is missed, then overcharging can occur. If one considers a long period of time or a period with many charging processes, then the electrochemical system in the battery leads to the destruction of the cell. This means that the batteries can no longer be loaded and cannot offer their full capacity.

Electronic chargers are also often referred to by manufacturers as intelligent devices and have complex charging circuits with a built-in microcontroller. This also allows more complex charging procedures to be implemented. The cells regenerate much faster after being charged and discharged several times, and the device has individual slot monitoring. This monitors the cell voltage and often also the cell temperature individually. Defective cells are identified and the independent charging of the individual charging bays avoids overcharging and not fully charging.

Mobile power sources are increasingly in demand due to the numerous uses of mobile end devices. These include the power bank, which is basically not a charger but an additional battery. Solar modules that are charged via a USB interface are also mobile power sources. They also belong to the regenerative power sources, as they use only solar power for charging.

Foto Erhardt offers you a wide range of different chargers and power supplies for every application and every type of end user. We have the right charger for every cell. From inexpensive entry-level chargers for small applications and devices to premium chargers for professional applications and the highest demands. The chargers meet today's needs and standards brought by our modern and digital world.

Simply subscribe and benefit as a newsletter recipient every week: